Transforming Chicken Waste Into Biofuel: a Guide"

Transform chicken waste into biofuel for sustainable energy. Reduce greenhouse gas emissions and waste disposal issues. Convert chicken manure, feathers, even eggshells into biofuels like biogasoline or biodiesel. Employ anaerobic digestion and thermochemical processes. Use bioreactors, distillation columns, and centrifuges for efficiency. Overcome challenges like methane release and economic feasibility. Adhere to regulations for safe production and market credibility. Tap into a growing $218.7 billion biofuel market. Ensure adherence to industry standards for quality and sustainability. Look into genetic modifications and waste-to-energy tech for future innovations. Start transforming chicken waste into biofuel today for a greener future.

Benefits of Biofuel From Chicken Waste

Have you ever wondered how converting chicken waste into biofuel can positively impact the environment and energy sector? When it comes to renewable energy sources, biofuels derived from chicken waste offer a promising solution. The environmental impact of utilizing chicken waste for biofuel production is significant. By converting this waste into a usable energy source, we can reduce greenhouse gas emissions, decrease reliance on fossil fuels, and mitigate the environmental issues associated with traditional waste disposal methods.

Biofuels from chicken waste provide a sustainable alternative to conventional energy sources. The process of converting chicken waste into biofuel helps in addressing two critical issues simultaneously: waste management and energy production. This renewable energy source not only reduces the environmental burden of waste disposal but also contributes to meeting the energy demands of various sectors.

The environmental benefits of utilizing chicken waste for biofuel production are substantial. By diverting organic waste from landfills and transforming it into a valuable energy resource, we can promote a circular economy and reduce the carbon footprint associated with traditional waste management practices. Embracing biofuels from chicken waste is a step towards a cleaner, more sustainable future for both the environment and the energy sector.

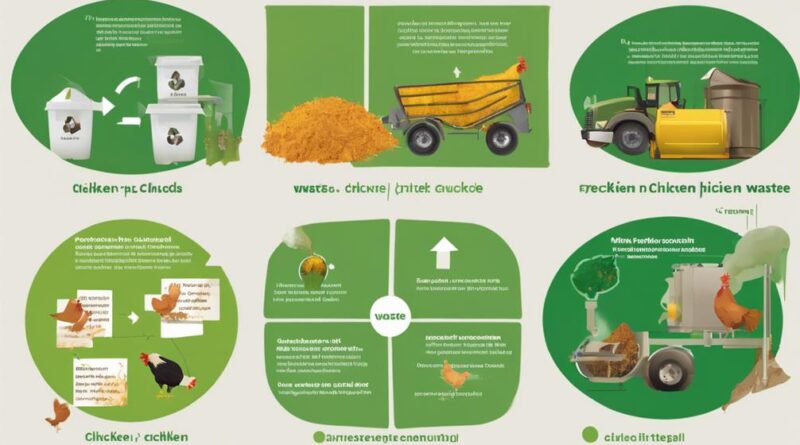

Types of Chicken Waste for Biofuel

Different types of chicken waste can be utilized for biofuel production, each offering unique advantages in the renewable energy sector. When considering the types of chicken waste for biofuel, it's essential to understand the specific characteristics and potential benefits they bring to the table:

- Manure: Chicken manure is a rich source of organic matter and nutrients, such as nitrogen and phosphorus. Its high nutrient content makes it a valuable resource for both nutrient recycling and biofuel production.

- Feathers: Chicken feathers, often considered as waste, are rich in keratin, a protein that can be converted into biofuel through various processes. Utilizing feathers for biofuel production not only reduces waste but also contributes to renewable energy generation.

- Bedding Materials: Wood shavings, straw, or recycled paper used as bedding materials in chicken coops can be repurposed for biofuel production. These materials, when processed correctly, can yield biofuels that are environmentally friendly and promote sustainability.

- Eggshells: While not directly used for biofuel, eggshells can play a role in nutrient recycling. By composting eggshells along with other organic waste, valuable nutrients can be returned to the soil, promoting healthier agricultural practices and supporting renewable energy initiatives.

Process of Converting Waste to Biofuel

What's the most efficient method for converting chicken waste into biofuel?

The process of converting waste to biofuel involves several key steps to ensure optimal biofuel production. Firstly, the waste conversion begins with the collection of chicken waste, including manure, feathers, and bedding materials. This waste is then transported to a biofuel production facility where the conversion process takes place.

Once the waste reaches the facility, it undergoes a series of steps to extract valuable biofuels. The waste is typically processed through anaerobic digestion, a biological process where microorganisms break down organic matter in the absence of oxygen. This process generates biogas, which consists primarily of methane and carbon dioxide. The biogas can be further refined to produce biofuels such as biogasoline, biodiesel, or biokerosene.

To enhance biofuel production efficiency, some facilities utilize thermochemical processes like pyrolysis or gasification. Pyrolysis involves heating the waste in the absence of oxygen to produce bio-oil, biochar, and syngas. Gasification converts the waste into syngas, which can be used to produce a variety of biofuels.

Equipment Needed for Biofuel Production

To optimize biofuel production from chicken waste, specific equipment such as bioreactors and distillation columns is essential in the biofuel production process. When setting up your biofuel production facility, the following equipment is crucial:

- Bioreactors:

These vessels provide an environment for the biological reactions that break down organic matter in the chicken waste and produce biofuels. Choosing bioreactors with efficient mixing systems can enhance energy efficiency by ensuring uniform conditions throughout the reactor.

- Distillation Columns:

Distillation columns are vital for separating the biofuel from other byproducts of the fermentation process. Opt for columns with multiple stages to achieve higher purity levels and improve cost-effectiveness by reducing the amount of energy required for distillation.

- Centrifuges:

Centrifuges help separate solid particles from the liquid biofuel product. By using high-speed rotation, centrifuges can increase the separation efficiency, contributing to cost savings and sustainable practices by reducing waste generation.

- Heat Exchangers:

Heat exchangers play a key role in maintaining optimal temperatures during various stages of biofuel production. Investing in efficient heat exchangers can improve energy efficiency and minimize environmental impact by reducing the overall energy consumption of the process.

Challenges in Chicken Waste Biofuel

Addressing the complex microbial interactions within chicken waste poses a significant challenge in optimizing biofuel production efficiency. The environmental impact of biofuel production from chicken waste is a key concern. The release of methane during the decomposition process of chicken waste can contribute to greenhouse gas emissions. To tackle this, technological advancements in anaerobic digestion processes are crucial. Enhancing the efficiency of microbial breakdown within the waste can minimize methane release, making the biofuel production process more environmentally friendly.

Moreover, economic feasibility plays a vital role in the widespread adoption of chicken waste biofuel. The cost of setting up biofuel production facilities, acquiring the necessary equipment, and ensuring regulatory compliance can be substantial. Finding cost-effective solutions, such as utilizing by-products from the biofuel production process, can enhance the economic viability of chicken waste biofuel.

Social acceptance is another challenge that must be addressed. Engaging with local communities, educating them about the benefits of biofuel production from chicken waste, and addressing any concerns regarding odor, waste management, or potential contamination are essential steps in gaining public support for such initiatives.

Regulations on Biofuel Production

Compliance with stringent regulatory frameworks is imperative for the efficient and sustainable production of biofuels from chicken waste. Ensuring regulatory compliance not only safeguards the environment but also promotes a thriving biofuel industry.

Here are key aspects to consider regarding regulations on biofuel production:

- Regulatory Compliance: Meeting regulatory requirements is crucial to guaranteeing the safe and environmentally friendly production of biofuels. Compliance with laws governing waste management, emissions, and fuel quality is essential to operate legally and responsibly.

- Environmental Impact: Regulations often focus on reducing the environmental footprint of biofuel production. Monitoring and mitigating factors such as greenhouse gas emissions, water usage, and land impact are vital to ensure that biofuel production from chicken waste remains sustainable.

- Government Incentives: Governments may offer incentives to promote biofuel production, such as tax credits, grants, or subsidies. Understanding and utilizing these incentives can help offset production costs and make biofuel production more economically viable.

- Industry Standards: Adhering to industry standards and certifications demonstrates a commitment to quality and sustainability. Conforming to recognized standards not only enhances credibility but also facilitates market access by meeting consumer and regulatory expectations.

Market Potential for Chicken Waste Biofuel

Exploring the market potential for chicken waste biofuel reveals promising opportunities for sustainable energy production. The economic opportunities in this sector are substantial. The global biofuel market is projected to reach $218.7 billion by 2027, with a compound annual growth rate of 8.4% from 2020 to 2027. Chicken waste biofuel can tap into this lucrative market by offering a cost-effective and eco-friendly alternative to traditional fossil fuels.

The environmental impact of chicken waste biofuel is equally significant. By converting chicken waste into biofuel, the process helps reduce greenhouse gas emissions and minimizes environmental pollution from poultry farms. This aligns with the growing global focus on sustainable energy sources and reducing carbon footprints. As governments worldwide implement stricter regulations on carbon emissions, the demand for renewable energy sources like chicken waste biofuel is expected to rise.

Investing in chicken waste biofuel presents an opportunity to not only generate profit but also contribute to a cleaner and greener future. By leveraging the economic opportunities and addressing environmental concerns, businesses can position themselves as key players in the transition towards sustainable energy solutions. Embracing this market potential can drive innovation, create jobs, and pave the way for a more environmentally conscious energy industry.

Future Innovations in Biofuel From Chickens

To propel advancements in biofuel derived from chickens, innovative research and development initiatives are crucial for maximizing efficiency and sustainability in energy production. In the quest for future innovations in biofuel from chickens, several key areas are being explored to enhance the viability of this renewable energy source:

- Genetic Modification: Scientists are investigating genetic modifications in chickens to enhance the lipid content in their waste, which can significantly boost the biofuel yield during the conversion process.

- Waste-to-Energy Technologies: Developing and implementing cutting-edge waste-to-energy technologies can streamline the conversion of chicken waste into biofuel, making the process more efficient and cost-effective.

- Nutrient Recovery: Exploring nutrient recovery techniques from chicken waste not only helps in biofuel production but also contributes to sustainable solutions by creating by-products that can be utilized in agriculture or other industries.

- Integrated Biorefinery Concepts: Implementing integrated biorefinery concepts that utilize various components of chicken waste for different purposes, such as biofuel production, fertilizer manufacturing, and energy generation, can maximize the overall value and sustainability of the biofuel production process.

Frequently Asked Questions

Can Biofuel From Chicken Waste Be Used in Household Vehicles?

Yes, biofuel derived from chicken waste can indeed be utilized in household vehicles. This sustainable fuel source helps reduce vehicle emissions, contributing to a cleaner environment.

The efficiency of biofuel from chicken waste is notable, showcasing its potential as a renewable energy alternative.

What Are the Potential Risks of Producing Biofuel From Chicken Waste?

When producing biofuel from chicken waste, you need to consider potential risks. Environmental impact is a key concern due to emissions and land use changes. Regulatory compliance is crucial to ensure safe handling and disposal of waste products.

Monitoring air and water quality, managing byproducts responsibly, and following strict guidelines can mitigate these risks. By prioritizing environmental sustainability and adhering to regulations, you can minimize the negative consequences associated with biofuel production from chicken waste.

How Does the Climate Impact the Efficiency of Chicken Waste Biofuel?

Climate variations can significantly impact the efficiency of chicken waste biofuel production. Fluctuations in temperature and precipitation levels can affect the decomposition process and the overall yield of biofuel.

Understanding these variations and adapting production processes can optimize the use of renewable energy sources like chicken waste for biofuel production. Monitoring and adjusting production methods based on climate patterns can enhance efficiency and sustainability in biofuel production.

Are There Any Health Concerns Associated With Using Chicken Waste Biofuel?

When using chicken waste biofuel, health concerns can arise due to potential exposure to harmful pathogens and emissions during the production process.

It's essential to follow strict regulatory standards to minimize risks and ensure safe handling practices.

Environmental impact studies also play a crucial role in assessing the overall sustainability of this biofuel source.

Can Chicken Waste Biofuel Production Be Sustainable in the Long Term?

In the long term, chicken waste biofuel production can be sustainable. Its environmental impact is favorable due to reduced greenhouse gas emissions compared to traditional fuels.

Economic viability is achievable through efficient conversion processes and potential government incentives.

Conclusion

You have learned about the benefits of transforming chicken waste into biofuel, the types of waste that can be used, the process of conversion, necessary equipment, challenges, regulations, market potential, and future innovations.

By utilizing chicken waste for biofuel production, you can contribute to sustainable energy solutions while also reducing waste and environmental impact.

Stay informed on advancements in biofuel technology to maximize the potential of this renewable energy source.