10 Best Automated Chicken Slaughtering Machines Reviewed

When looking for the top automated chicken slaughtering machines, focus on enhancing efficiency, precision, safety, maintenance, and cost-effectiveness. Seek machines with advanced designs, automated features like blade sharpening, and improved sensors. Consider technologies that minimize environmental impact and prioritize animal welfare. Opt for systems with precise cuts, strict safety measures, and easy cleaning protocols. Look for ergonomic designs, uniform cutting capabilities, and contamination-free processing. Prioritize machines that preserve juiciness, offer user-friendly interfaces, and ensure durability. Analyze long-term savings and operational efficiency. The details matter in selecting the best automated chicken slaughtering machines.

Efficiency and Performance

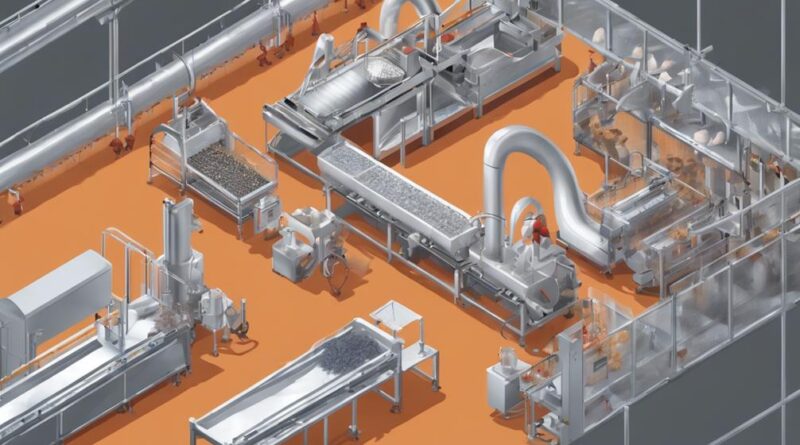

How do these automated chicken slaughtering machines perform in terms of efficiency and speed? When looking at the current market offerings, it's clear that manufacturers have made significant strides in improving the design and enhancing the functionality of these machines.

The improved design of automated chicken slaughtering machines allows for smoother operations and increased efficiency. With features like automated blade sharpening mechanisms and self-cleaning systems, downtime for maintenance is minimized, ensuring a continuous workflow. These advancements in design not only reduce the need for manual intervention but also contribute to overall speed and productivity.

In terms of functionality, the latest automated chicken slaughtering machines boast enhanced capabilities that streamline the entire slaughtering process. From automated evisceration and deboning functions to integrated quality control systems, these machines are equipped to handle various tasks with precision and consistency. The incorporation of advanced sensors and monitoring devices further ensures optimal performance and product quality.

Advanced Slaughtering Technology

The integration of cutting-edge technology in automated chicken slaughtering machines revolutionizes the efficiency and precision of the slaughtering process. These advanced machines have significantly reduced the environmental impact of poultry processing by incorporating sustainable practices. Utilizing innovative techniques, such as water recycling systems and energy-efficient components, these machines aim to minimize waste and conserve resources, making them more environmentally friendly compared to traditional methods.

Moreover, ethical considerations and animal welfare are at the forefront of the design of these advanced slaughtering technologies. By implementing features that prioritize the humane treatment of chickens throughout the slaughtering process, these machines adhere to strict guidelines to ensure minimal distress to the animals. From automated stunning mechanisms to swift and accurate processing procedures, these technologies aim to enhance animal welfare standards in the poultry industry.

Precision in Processing Chickens

With the focus on precision in processing chickens, the automated slaughtering machines incorporate cutting-edge technology to ensure accurate and efficient procedures. These machines are designed to meet regulatory compliance and industry standards while also considering ethical considerations and sustainability.

Here's how precision is achieved in processing chickens:

- Advanced Sensor Technology: Automated chicken slaughtering machines utilize advanced sensors to precisely identify the position of each chicken, ensuring precise cuts and minimizing errors in the process. These sensors help maintain consistency in the processing line, enhancing efficiency and accuracy.

- Computerized Cutting Mechanisms: The machines are equipped with computerized cutting mechanisms that are programmed to make precise cuts based on the size and weight of each chicken. This automation reduces human error and ensures that the processing is done with utmost accuracy.

- Real-time Monitoring and Adjustment: To maintain precision throughout the processing, these machines are equipped with real-time monitoring systems that track various parameters such as blade sharpness, cutting angles, and line speeds. Any deviation from the set parameters triggers automatic adjustments, ensuring that each chicken is processed with precision and uniformity.

Top Safety Features

Implementing a comprehensive array of safety features ensures the secure operation of automated chicken slaughtering machines. These machines must adhere to strict safety regulations to protect both operators and the quality of the final product. One key aspect of safety is the ergonomic design of the machine. Ergonomics plays a crucial role in reducing operator fatigue and the risk of repetitive strain injuries, ensuring that workers can efficiently and safely operate the equipment over extended periods.

Operator training is another vital component of ensuring safety when using automated chicken slaughtering machines. Proper training not only enhances productivity but also minimizes the chances of accidents. Operators must be well-versed in the correct procedures for operating the machines and handling emergencies effectively.

Additionally, emergency stop features are crucial for quickly halting machine operations in case of a malfunction or potential hazard. These features provide operators with the ability to swiftly stop the machine, preventing accidents and injuries.

Easy Maintenance and Cleaning

To ensure optimal performance and longevity of automated chicken slaughtering machines, regular maintenance and thorough cleaning are essential. Neglecting these tasks can lead to decreased efficiency, potential breakdowns, and increased downtime. Here's how you can effectively maintain and clean your automated chicken slaughtering machine:

- Cleaning Protocols: Develop detailed cleaning protocols that outline the specific steps required to clean each part of the machine. Use appropriate cleaning agents and tools to ensure thorough removal of any debris or residue. Regular cleaning not only improves hygiene but also prevents the buildup of contaminants that can affect the machine's performance.

- Maintenance Schedules: Create a comprehensive maintenance schedule that includes routine inspections, lubrication of moving parts, and replacement of worn-out components. Adhering to a structured maintenance plan can help identify potential issues early on, reducing the risk of unexpected breakdowns. Keep detailed records of maintenance activities and consider implementing preventive maintenance measures to extend the lifespan of your machine.

- Spare Parts: Maintain an inventory of essential spare parts to quickly address any malfunctions or failures. Having spare parts readily available can minimize downtime and ensure that repairs are completed promptly. Regularly review and update your spare parts inventory based on usage patterns and recommendations from the manufacturer.

Speed and Productivity

Achieving optimal speed and productivity in automated chicken slaughtering machines requires precise calibration of operational parameters and strategic workflow planning. To enhance efficiency, manufacturers implement cost-saving measures through the integration of advanced technologies like automated evisceration systems and robotic deboning equipment. These systems not only streamline the slaughtering process but also reduce the reliance on manual labor, thereby optimizing workforce productivity.

The impact of improved speed and productivity extends beyond operational efficiency. By minimizing manual intervention and automating repetitive tasks, companies can create a safer and more ergonomic work environment for employees. This, in turn, enhances overall employee satisfaction and reduces the risk of injuries associated with repetitive motions. Additionally, the implementation of automated systems reduces the physical strain on workers, leading to a more comfortable and efficient production line.

Striking a balance between speed, productivity, and employee well-being is crucial for the successful integration of automated chicken slaughtering machines. By prioritizing labor optimization and implementing cost-saving measures through automation, companies can't only boost their production output but also create a more sustainable and employee-friendly work environment.

Quality of Final Chicken Products

To ensure the highest quality of final chicken products, meticulous attention to detail in the automated slaughtering process is imperative for meeting consumer standards and satisfaction. The taste preferences of consumers play a significant role in determining the quality of the final chicken products.

Here are three key factors to consider in optimizing the quality of the final chicken products:

- Uniformity of Cuts: Consistency in the cutting process is crucial for ensuring that the chicken pieces are of uniform size and shape. This uniformity not only enhances the visual appeal of the final product but also ensures even cooking, resulting in a better overall dining experience for consumers.

- Minimal Contamination: Keeping the chicken meat free from contamination during the slaughtering process is essential for maintaining quality and safety standards. Automated machines should be designed to minimize contact with harmful bacteria and pathogens, thus preserving the freshness and quality of the final chicken products.

- Preservation of Juiciness: Retaining the natural juices and flavors of the chicken meat is key to meeting consumer taste preferences. Automated slaughtering machines should prioritize methods that prevent excessive moisture loss, resulting in tender and juicy chicken products that satisfy consumer expectations and enhance consumer satisfaction.

User-Friendly Interface Design

Efficiently designed user interfaces on automated chicken slaughtering machines are essential for optimizing operational performance and ensuring seamless interaction for operators. When considering user experience, ergonomic design plays a crucial role in minimizing operator fatigue and maximizing efficiency. The placement of controls, buttons, and displays should be intuitive, allowing operators to navigate the machine's functions with ease.

Intuitive controls are paramount in ensuring that operators can quickly understand and operate the automated chicken slaughtering machine without extensive training. Accessibility is another key aspect of user-friendly interface design. Buttons and controls should be within reach and easy to manipulate, reducing the risk of errors during operation. Additionally, clear labeling and color-coded indicators can further enhance the user experience by providing quick visual cues.

Ergonomics should also be taken into account when designing the interface of automated chicken slaughtering machines. The layout of the controls should promote natural hand movements and minimize strain on the operator's body. By prioritizing user-friendly interface design, manufacturers can create a more efficient and operator-friendly machine that enhances productivity and reduces the likelihood of errors during operation.

Durability and Longevity

Considering the demands of continuous operation in industrial settings, the focus shifts to the durability and longevity of automated chicken slaughtering machines. When investing in such equipment, ensuring long term sustainability and equipment reliability is crucial to maintain efficiency and minimize downtime.

Here are key factors to consider:

- Material Quality: Opt for machines constructed from high-grade stainless steel or other corrosion-resistant materials. These materials aren't only durable but also contribute to the longevity of the equipment by reducing wear and tear over time.

- Maintenance Requirements: Look for machines that have straightforward maintenance procedures outlined in the manual. Regular maintenance is essential for ensuring the equipment operates optimally for an extended period. Consider machines with easily accessible components for quick servicing.

- Warranty and Support: Choose machines from manufacturers that offer comprehensive warranties and reliable customer support. A good warranty provides peace of mind regarding potential repairs or replacements. Additionally, responsive customer support can assist in troubleshooting issues promptly, enhancing the overall equipment reliability.

Cost-Effectiveness and Value

When evaluating the cost-effectiveness and value of automated chicken slaughtering machines, analyzing the initial investment alongside long-term operational savings is crucial for informed decision-making. To determine the cost-effectiveness of a machine, it's essential to consider not only the purchase price but also factors such as maintenance costs, energy consumption, and potential cost-saving measures that the machine may offer.

Automated chicken slaughtering machines can provide significant cost-saving measures over time. These machines are designed to streamline the slaughtering process, reducing the need for manual labor and minimizing errors. By increasing efficiency and productivity, these machines can lead to long-term operational savings for poultry processing facilities. Additionally, automated machines can help reduce waste and improve yield, further contributing to cost savings.

When calculating the return on investment for automated chicken slaughtering machines, it's important to consider the machine's lifespan, maintenance requirements, and potential for increased production. While the initial investment may seem significant, the long-term benefits of reduced labor costs, improved efficiency, and higher product quality can make these machines a valuable asset for poultry processing facilities looking to optimize their operations and maximize profitability.

Frequently Asked Questions

Can These Machines Be Customized to Accommodate Different Chicken Sizes?

Yes, these machines can be customized to accommodate various chicken sizes, enhancing slaughtering efficiency. Customization options typically include adjustable conveyor belts, cutting blades, and sizing guides.

Are There Any Options Available for Monitoring and Controlling the Slaughtering Process Remotely?

For remote monitoring and control options in automated chicken slaughtering machines, advanced automation technology offers efficiency benefits. Various systems allow you to oversee and manage the slaughtering process from a distance, ensuring precision and safety.

These features streamline operations and enhance productivity. By leveraging remote monitoring capabilities, you can optimize the efficiency of your chicken slaughtering operations while maintaining control and oversight.

Do These Machines Have the Capability to Handle Organic or Free-Range Chickens?

When it comes to automated chicken slaughtering machines, they can typically handle organic or free-range chickens efficiently. These machines are designed to cater to various types of poultry, ensuring slaughtering efficiency regardless of the chicken's rearing method.

For farms seeking organic certification, it's essential to choose machines that align with sustainability practices and prioritize humane handling. Selecting the right automated slaughtering equipment can contribute significantly to meeting organic standards and maintaining ethical practices.

Can These Machines Be Integrated With Existing Poultry Processing Equipment?

When considering integration compatibility, these machines can be seamlessly integrated with existing poultry processing equipment to enhance efficiency.

Their customization flexibility allows for adjustments to meet specific production volume needs.

By incorporating these automated chicken slaughtering machines into your processing line, you can streamline operations and optimize output.

The ability to tailor settings and processes ensures a smooth transition and increased productivity in your poultry processing facility.

Is There a Warranty or Service Plan Included With the Purchase of These Machines?

When you invest in these automated chicken slaughtering machines, you'll benefit from comprehensive maintenance coverage and extended warranties.

The purchase includes technical support to address any issues that may arise, along with access to repair services if needed.

This warranty and service plan ensures that your equipment remains in optimal condition, allowing you to streamline your poultry processing operations efficiently and effectively.

Conclusion

In conclusion, when considering the best automated chicken slaughtering machines, it's crucial to prioritize:

- Efficiency

- Advanced technology

- Precision

- Safety features

- Ease of maintenance

- Quality of final products

- User-friendly interface design

- Durability

- Longevity

- Cost-effectiveness

- Overall value

By carefully evaluating these factors, you can ensure that you invest in a machine that meets your specific needs and delivers optimal performance in processing chickens. Choose wisely to maximize productivity and achieve top-notch results in poultry processing.