Top Innovations Transforming Chicken Product Processing"

You might be surprised by the latest advancements reshaping the chicken product processing landscape. From cutting-edge technology like automated cutting systems to innovative packaging solutions and intelligent sorting machines, the industry is undergoing a significant transformation. These top innovations are not only streamlining operations but also enhancing product quality and safety. Stay tuned to discover how these advancements are revolutionizing the way chicken products are processed and setting new standards for efficiency and sustainability in the industry.

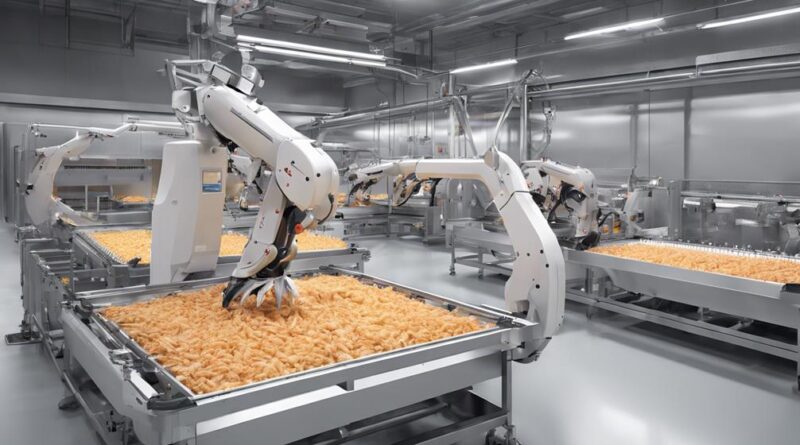

Automated Cutting Technology

Automated cutting technology revolutionizes chicken processing by streamlining precision cutting tasks with efficiency and accuracy. This innovation involves the use of robotic precision to ensure consistent and uniform cuts in chicken products. Automated slicing machines are equipped with advanced sensors and cutting mechanisms that can adapt to different sizes and shapes of chicken pieces, optimizing the yield from each bird.

Robotic precision in automated cutting technology allows for increased productivity in chicken processing plants. These machines can operate at high speeds while maintaining precise cutting measurements, reducing human error and ensuring the quality of the final product. By incorporating automated slicing into the production line, processing plants can achieve a higher output with fewer resources, making the operation more cost-effective and sustainable in the long run.

The automated slicing process begins with the chickens moving along a conveyor belt towards the cutting machine. As each bird reaches the designated cutting area, the robotic arms swiftly and accurately slice the meat into desired portions. This method not only saves time but also ensures a consistent product that meets the required specifications. Overall, automated cutting technology represents a significant advancement in the chicken processing industry, enhancing efficiency, accuracy, and overall product quality.

Enhanced Packaging Solutions

Enhancing the efficiency and sustainability of chicken product processing, cutting-edge packaging solutions incorporate advanced technologies and materials to optimize product preservation and presentation. Eco-friendly packaging plays a crucial role in reducing environmental impact. These innovative solutions utilize biodegradable materials, recyclable packaging, and reduced plastics to ensure a more sustainable approach to packaging chicken products.

Traceability solutions are another key aspect of enhanced packaging in the chicken processing industry. By incorporating technologies like RFID tags, QR codes, and barcodes, companies can track the entire journey of the product from farm to shelf. This not only enhances food safety by enabling quick recalls if necessary but also provides consumers with valuable information about the origin of the chicken product they're purchasing.

Moreover, these advanced packaging solutions go beyond basic containment and protection. They're designed to extend the shelf life of chicken products through modified atmosphere packaging, vacuum packaging, and antimicrobial packaging materials. By controlling factors like oxygen levels, humidity, and temperature, these packaging solutions help maintain the freshness and quality of the chicken products for a longer duration.

Intelligent Sorting Systems

Integrating cutting-edge technology into the chicken product processing industry, the implementation of intelligent sorting systems revolutionizes the efficiency and accuracy of sorting poultry products. AI-powered grading and robotic handling are at the forefront of this innovation, offering precise and efficient sorting capabilities that were once unimaginable.

In this realm of intelligent sorting systems, the following key features stand out:

- AI-Powered Grading: Utilizing advanced artificial intelligence algorithms, these sorting systems can analyze multiple aspects of each chicken product, including weight, size, quality, and even potential defects. This results in a highly accurate and consistent grading process, ensuring that each product meets the specified standards.

- Robotic Handling: By incorporating robotic arms and grippers, these systems can efficiently sort and package chicken products with speed and precision. The robotic handling not only enhances the overall efficiency of the processing line but also reduces the risk of contamination and human errors.

- Data Integration: Intelligent sorting systems are capable of seamlessly integrating with existing data management systems, providing real-time information on sorting metrics, production rates, and quality control. This data-driven approach allows for continuous optimization of the sorting process.

- Adaptability and Flexibility: These systems are designed to be adaptable to different product types and processing requirements, ensuring versatility in handling various chicken products effectively.

The integration of AI-powered grading and robotic handling in intelligent sorting systems represents a significant leap forward in the chicken product processing industry, offering enhanced efficiency, accuracy, and quality control.

High-Speed Deboning Machines

Utilizing cutting-edge technology, high-speed deboning machines streamline the poultry processing industry by enhancing efficiency and precision in separating meat from the bone. These machines are equipped with robotics integration, allowing for automated and precise removal of meat from chicken carcasses at remarkable speeds. By incorporating advanced sensors and imaging systems, high-speed deboning machines can detect bones with high accuracy, ensuring minimal meat wastage and increased production efficiency.

The robotics integration in these machines enables them to adapt to different sizes and shapes of chicken parts, making the deboning process versatile and efficient. Through a combination of robotic arms, high-resolution cameras, and cutting tools, these machines can swiftly debone large quantities of chicken, significantly reducing the need for manual labor and increasing overall productivity.

Production efficiency is a key focus of high-speed deboning machines. By automating the deboning process, these machines can handle a high volume of chicken parts consistently and quickly, leading to a more streamlined production line. This efficiency not only saves time but also reduces costs associated with manual labor and potential errors in the deboning process. Overall, high-speed deboning machines revolutionize chicken processing plants by improving precision, speed, and productivity in meat separation.

Advanced Marination Techniques

Advanced marination techniques optimize the flavor and tenderness of chicken products through cutting-edge methods that enhance taste and texture profiles. Marination optimization plays a crucial role in the poultry industry, ensuring that consumers experience high-quality, flavorful chicken products. By incorporating innovative flavor infusion techniques, manufacturers can elevate the overall sensory experience of their chicken offerings.

- Microbial Marination: Introducing beneficial microbes into the marination process can't only enhance flavor but also contribute to the tenderization of chicken meat through enzymatic action.

- Vacuum Tumbling: Utilizing vacuum tumbling technology allows for a more efficient and uniform distribution of marinade, ensuring that each piece of chicken is thoroughly infused with flavor.

- Injection Technology: Advanced injection systems can precisely control the amount and distribution of marinade, leading to consistent flavor profiles and improved product quality.

- Brine Solutions: Customized brine solutions with optimized salt and seasoning levels can significantly impact the final taste and texture of marinated chicken products.

Precision Slaughtering Equipment

Precision slaughtering equipment plays a pivotal role in ensuring the efficiency and accuracy of poultry processing operations, ultimately contributing to the quality and safety of chicken products. In today's poultry processing plants, AI-driven efficiency and robotic handling technologies have revolutionized the way chickens are slaughtered and processed.

AI-driven efficiency in precision slaughtering equipment involves the use of advanced algorithms and sensors to optimize the processing line. These systems can analyze data in real-time, allowing for adjustments to be made instantly to enhance the speed and accuracy of the slaughtering process. By incorporating AI, processors can streamline operations, reduce waste, and ensure a more consistent end product.

Robotic handling technologies have also significantly impacted precision slaughtering. Robots equipped with precise cutting tools can efficiently and accurately separate the different parts of the chicken carcass with minimal waste. Additionally, robotic systems can handle delicate tasks with consistency, reducing human error and improving overall product quality.

The integration of AI-driven efficiency and robotic handling technologies in precision slaughtering equipment represents a significant advancement in chicken processing. These innovations not only increase productivity and cost-effectiveness but also enhance food safety by providing a more controlled and standardized processing environment.

Quality Control Automation Tools

Implementing automated quality control tools enhances the efficiency and consistency of chicken product processing operations, ensuring adherence to strict quality standards throughout the production line. These tools are revolutionizing the industry by incorporating robotic inspection and data analytics to improve the overall process. Here's how these innovations are shaping the future of chicken product processing:

- Robotic Inspection: Automated systems equipped with advanced robotic technology can perform intricate quality checks with precision and speed, detecting defects or inconsistencies that may be missed by the human eye. This ensures that only products meeting the highest standards are approved for further processing.

- Data Analytics: By utilizing data analytics, processing plants can gather real-time information on various quality parameters, allowing for immediate adjustments to optimize production efficiency and maintain quality control standards. This data-driven approach enables proactive decision-making and continuous improvement in the processing operations.

- Enhanced Efficiency: Automated quality control tools significantly reduce the time and resources required for manual inspections, leading to a more streamlined production process. This efficiency not only increases output but also minimizes the risk of errors, ensuring a higher level of consistency in the final products.

- Quality Assurance: With automated tools handling quality control tasks, there's a higher level of confidence in the quality and safety of the chicken products. This not only meets regulatory requirements but also enhances consumer trust in the brand's commitment to delivering top-quality products.

Sustainable Waste Management Systems

To optimize sustainability in chicken product processing, the integration of innovative waste management systems is crucial for maximizing resource efficiency and minimizing environmental impact. One key aspect of sustainable waste management in this context is the use of biodegradable packaging. Biodegradable packaging materials break down naturally into non-toxic components, reducing the environmental footprint of the chicken processing industry.

Composting solutions are another essential component of sustainable waste management systems. Through composting, organic waste generated during chicken processing can be converted into nutrient-rich soil amendments. This not only diverts waste from landfills but also creates a valuable resource that can be used in agriculture, completing a sustainable cycle of resource use.

Implementing advanced waste separation techniques is vital for effective waste management. By segregating different types of waste at the source, such as packaging materials, food scraps, and non-recyclable items, the efficiency of recycling and composting processes can be significantly increased. This not only reduces the amount of waste destined for landfills but also conserves valuable resources by enabling the recovery of materials that can be repurposed or recycled.

Frequently Asked Questions

How Do These Innovations Impact the Taste and Quality of Chicken Products?

When it comes to taste improvement and quality assurance in chicken products, innovative processing methods have a significant impact. These advancements enhance flavor profiles through precision cooking techniques and quality control measures.

By ensuring optimal cooking temperatures and reducing processing times, these innovations help maintain the juiciness and tenderness of the chicken, resulting in a superior dining experience.

What Are the Environmental Benefits of Utilizing These Advanced Technologies?

Utilizing advanced technologies in chicken processing brings sustainability benefits by reducing water and energy usage. Efficiency improvements through automation minimize waste and carbon footprint.

These innovations lower overall environmental impact by streamlining production processes and optimizing resource utilization. Embracing these advancements not only enhances operational efficiency but also contributes to a more sustainable and eco-friendly approach to chicken product processing.

Can These Advancements Lead to Cost Savings for Chicken Processing Plants?

When you consider advancements in chicken processing, cost efficiency and operational improvements are key. These innovations can indeed lead to substantial cost savings for processing plants. By streamlining operations, reducing waste, and optimizing production processes, plants can achieve higher efficiency levels, ultimately resulting in significant financial benefits.

Embracing these cutting-edge technologies not only enhances productivity but also contributes to the overall sustainability and profitability of chicken processing operations.

Are There Any Potential Job Implications for Workers in the Industry?

When considering the potential job implications in the industry, job automation is a critical aspect. With advancements in technology, certain tasks may become automated, impacting the workforce.

However, this also underscores the importance of workforce training to adapt to these changes. By investing in upskilling and reskilling programs, workers can be better prepared for evolving roles and emerging opportunities within the chicken product processing industry.

How Do These Innovations Address Food Safety Concerns in Chicken Processing?

In addressing food safety concerns in chicken processing, pathogen reduction is achieved through advanced technology integration. Automation plays a vital role in streamlining processes, reducing human error.

Hygiene improvements are emphasized in these innovations, ensuring a clean processing environment. By incorporating these cutting-edge solutions, the industry can enhance food safety standards and mitigate potential risks associated with poultry products.

Conclusion

You have witnessed the cutting-edge innovations revolutionizing chicken product processing. From automated cutting technology to sustainable waste management systems, these advancements have significantly improved efficiency and product quality.

With intelligent sorting systems and high-speed deboning machines, the industry is evolving towards a more sustainable and efficient future.

Embrace these transformative technologies to ensure the highest standards in chicken processing and delivery to consumers. Stay at the forefront of innovation to lead the way in this rapidly evolving industry.