Why Invest in Advanced Chicken Processing Equipment?"

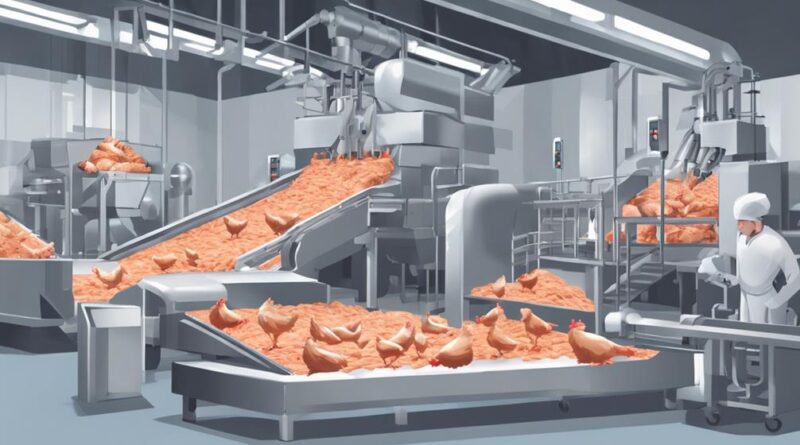

Investing in advanced chicken processing equipment can revolutionize your poultry processing operations. Imagine a scenario where precision, speed, and quality converge to redefine your output standards. Efficiency is not just a goal but a reality, allowing you to meet market demands with ease. But there's more to this investment than meets the eye. Stay tuned to discover the hidden advantages that could transform your facility into a cutting-edge operation in the competitive poultry industry.

Efficiency in Processing

To maximize productivity in chicken processing, it's essential to streamline operations through the implementation of advanced equipment and automation technologies. By incorporating cutting-edge machinery into your processing line, you can significantly increase output while simultaneously reducing the need for manual labor.

One key aspect of maximizing output is the integration of automated cutting and deboning machines. These machines can efficiently and accurately process a high volume of chicken carcasses, reducing the reliance on manual labor for these repetitive tasks. By automating these processes, you not only speed up production but also ensure consistency in the quality of cuts, leading to a more efficient overall operation.

Furthermore, investing in advanced chilling and freezing technologies can also contribute to enhancing efficiency in chicken processing. Rapid chilling and freezing equipment can significantly reduce processing times, allowing for quicker turnaround and maximizing output capacity. This not only streamlines operations but also helps in meeting tight production deadlines and maintaining product quality.

Improved Product Quality

Enhance the overall product quality by implementing advanced inspection and grading systems in chicken processing operations. By incorporating these systems, you can ensure that only the highest quality chicken products reach the market. Advanced inspection technology can detect any abnormalities or defects in the chicken, leading to improved overall product quality. This not only benefits the consumers but also enhances the reputation of your brand in the market.

When it comes to chicken processing, achieving enhanced flavor profiles is crucial. Advanced equipment can help maintain the quality and consistency of the flavor of the chicken products. By ensuring that each piece of chicken meets the desired flavor profile, you can satisfy customer preferences and increase brand loyalty.

Consistent texture control is another key aspect of product quality in chicken processing. Advanced processing equipment allows for precise control over the texture of the chicken products, ensuring uniformity and meeting consumer expectations. Whether it's the tenderness of a chicken breast or the juiciness of a drumstick, consistent texture control plays a vital role in delivering high-quality products to the market.

Investing in advanced chicken processing equipment not only elevates the quality of your products but also sets you apart from competitors. Enhanced flavor profiles and consistent texture control are essential elements in meeting consumer demands and building a strong brand presence in the market.

Enhanced Food Safety Measures

Implementing rigorous food safety protocols is imperative for ensuring the highest standards of quality and consumer protection in chicken processing operations. Advanced chicken processing equipment plays a vital role in enhancing food safety measures, ultimately leading to improved health benefits for consumers and fostering increased consumer trust in the brand.

One key aspect of enhanced food safety measures is the utilization of cutting-edge technology in equipment design. For instance, equipment with automated temperature control and monitoring systems helps prevent bacterial growth and contamination during processing. By maintaining precise temperatures at critical control points, the risk of foodborne illnesses is significantly reduced, providing health benefits to consumers who enjoy chicken products.

Moreover, investing in advanced equipment that incorporates features such as integrated sanitation systems and easy-to-clean surfaces enhances overall food safety. These elements streamline cleaning processes, minimize cross-contamination risks, and ensure compliance with stringent hygiene standards. As a result, consumers can trust that the chicken products they purchase have been processed using the latest safety measures, reassuring them of the quality and integrity of the brand.

Increased Production Capacity

Utilizing advanced chicken processing equipment can significantly boost production capacity, allowing for increased throughput and efficiency in your operations. By investing in modern machinery, you open up expansion opportunities and streamline processes for maximum output.

One of the key benefits of advanced chicken processing equipment is the optimization of labor resources. These machines are designed to handle tasks that would traditionally require significant manual labor, thereby reducing the reliance on human input for repetitive or strenuous activities. This labor optimization not only increases productivity but also enhances workplace safety by minimizing the risk of injuries associated with manual handling.

Furthermore, the integration of cutting-edge technology into your processing line enhances market competitiveness. With state-of-the-art equipment, you can meet the growing demands of consumers for high-quality chicken products efficiently. This not only allows you to keep up with market trends but also potentially gain a competitive edge by offering superior products at a faster pace than competitors.

Cost Savings in the Long Run

Maximizing operational efficiency through the adoption of advanced chicken processing equipment results in significant long-term cost savings. Investing in such equipment is a strategic long-term investment that brings various operational benefits, ultimately leading to financial savings over time. By utilizing cutting-edge technology in chicken processing, you can streamline production processes, reduce labor costs, and minimize waste, all of which contribute to significant cost efficiencies in the long run.

One key aspect of the cost savings derived from advanced chicken processing equipment is the reduction in labor expenses. Automated systems and machinery can perform tasks that would otherwise require manual labor, leading to decreased labor costs and increased productivity. This operational efficiency not only saves money but also enhances overall output capacity.

Furthermore, the precision and accuracy offered by advanced equipment minimize errors in processing, leading to less product wastage. This reduction in waste translates to direct cost savings by maximizing the yield from each chicken processed. Additionally, the improved quality control mechanisms in modern processing equipment help in maintaining product consistency and reducing the likelihood of costly recalls or reprocessing.

Compliance With Industry Standards

By aligning with established industry standards, your investment in advanced chicken processing equipment ensures regulatory compliance and upholds quality benchmarks within the poultry processing sector. Compliance with industry standards is crucial to guarantee the safety and quality of your processed chicken products.

Here are some key aspects to consider:

- Regulatory Requirements: Advanced chicken processing equipment is designed to meet stringent regulatory standards set by authorities. Ensuring compliance with these regulations not only keeps your operations legal but also builds trust with consumers.

- Technology Integration: Modern equipment integrates cutting-edge technologies that help streamline processes, enhance food safety measures, and improve overall efficiency. By investing in such technology, you stay ahead in meeting industry standards.

- Quality Control Measures: Advanced equipment often comes with built-in quality control features that monitor various parameters during processing. This ensures that your chicken products consistently meet the desired quality standards.

- Traceability Systems: Many advanced processing equipment options offer traceability features that help track the product journey from farm to table. This level of transparency is essential for meeting industry standards and ensuring food safety.

- Training and Support: Manufacturers of advanced processing equipment often provide training programs and ongoing support to ensure your team can operate the machinery effectively and in accordance with industry best practices.

Minimized Risk of Contamination

To enhance food safety and minimize the risk of contamination in poultry processing, investing in advanced chicken processing equipment with integrated sanitation protocols is paramount. Advanced equipment such as automated evisceration machines and precision cutting tools not only increase efficiency but also significantly reduce the chances of cross-contamination during processing. By utilizing equipment with self-cleaning mechanisms and antimicrobial surfaces, the risk of bacterial growth and contamination is further minimized.

Reducing waste is a key benefit of investing in advanced chicken processing equipment. Through precise cutting and portioning capabilities, these machines ensure that each part of the chicken is utilized efficiently, minimizing discarded portions and reducing overall waste. This not only improves cost-effectiveness but also contributes to a more sustainable processing operation.

Optimizing workflow is another crucial aspect influenced by advanced processing equipment. By streamlining processes such as deboning, portioning, and packaging, these machines help maintain a consistent and efficient workflow. This optimization not only enhances productivity but also reduces the time chicken spends in the processing line, decreasing the potential for contamination and ensuring a higher level of food safety.

Streamlined Workflow and Operations

Enhance operational efficiency in poultry processing by implementing advanced equipment for streamlined workflow and optimized operations. Improved sanitation and an optimized layout play a crucial role in achieving this goal. By investing in advanced chicken processing equipment, you can significantly improve your facility's workflow and overall operations. Here are five key benefits:

- Improved Sanitation: Advanced equipment often comes with features that enhance sanitation practices, such as self-cleaning mechanisms and materials designed to resist bacterial growth. This helps maintain a hygienic processing environment and reduces the risk of contamination.

- Optimized Layout: Modern equipment is designed with efficiency in mind, allowing for a more streamlined layout that minimizes unnecessary movement and reduces processing time. This optimized layout can lead to a smoother workflow and increased productivity.

- Enhanced Traceability: Advanced equipment often includes digital tracking systems that allow you to monitor each step of the processing chain. This enhanced traceability not only improves quality control but also facilitates compliance with industry regulations.

- Reduced Labor Costs: Automated features in advanced equipment can help streamline operations and reduce the need for manual labor. This can lead to cost savings in the long run and free up employees to focus on more specialized tasks.

- Increased Output: By optimizing workflow and operations with advanced equipment, you can increase your processing capacity and meet growing demand more effectively. This can lead to higher profitability and a competitive edge in the market.

Frequently Asked Questions

What Are the Maintenance Requirements for Advanced Chicken Processing Equipment?

To keep your advanced chicken processing equipment running smoothly, it's crucial to adhere to regular maintenance schedules. By following the manufacturer's guidelines, you can prevent breakdowns and ensure optimal performance.

In case of issues, a systematic troubleshooting process can help identify and fix problems efficiently. Regular maintenance and a structured troubleshooting approach are key to maximizing the efficiency and longevity of your advanced chicken processing equipment.

How Do Advanced Machines Impact the Environmental Sustainability of the Facility?

When considering how advanced machines impact the environmental sustainability of the facility, it's essential to note the significant benefits they offer. Reduced waste and enhanced energy efficiency are key advantages.

These machines streamline processes, leading to less material wastage and lower energy consumption. By investing in advanced equipment, your facility can operate more sustainably, minimizing its environmental footprint and contributing to a greener future.

Can Advanced Equipment Be Customized to Suit Specific Processing Needs?

When considering advanced chicken processing equipment, you'll find that customization options play a crucial role. These machines can be tailored to suit specific processing needs, enhancing efficiency improvements.

Are There Training Programs Available for Employees to Operate New Machinery?

When it comes to operational efficiency, having structured employee training programs is paramount. These programs ensure that your staff can effectively operate new machinery, maximizing productivity and reducing errors.

By investing in training, you empower your employees to handle advanced equipment with confidence, ultimately leading to smoother operations and higher output.

Employee training isn't just a necessity; it's a strategic move towards achieving optimal performance in your chicken processing facility.

How Does Advanced Equipment Integrate With Existing Processing Infrastructure?

When it comes to integrating advanced equipment with existing processing infrastructure, you may encounter some challenges related to compatibility and workflow optimization. However, by carefully assessing these integration challenges and making necessary adjustments, you can significantly enhance operational efficiency.

Streamlining processes, minimizing downtime, and maximizing output are key goals that can be achieved through the seamless integration of advanced chicken processing equipment with your current infrastructure.

Conclusion

In conclusion, investing in advanced chicken processing equipment is essential for maximizing efficiency, ensuring product quality, and meeting food safety regulations. With increased production capacity, cost savings, and compliance with industry standards, the benefits are clear.

By minimizing the risk of contamination, streamlining operations, and optimizing workflow, poultry processing facilities can achieve sustainable and profitable outcomes. Make the smart choice to invest in advanced equipment for a competitive edge in the poultry industry.